We focus on versatility and the possibility of quick conversion so as to ensure wide possibilities of producing short series of products.

We offer high-quality autonomous components dedicated to small cosmetics producers. They allow for a significant improvement in packaging and production processes without large investment outlays.

If you need high capacities for one type of product, please contact us and see our offer for monoblocks.

We offer you a proven design of feeding pumps with the possibility of self-priming. They are perfect for dispensing products from containers to the hoppers of production cells. They are characterized by efficiency, reliability and the possibility of quick disassembly and cleaning of all components of the pump, which greatly facilitates its operation. In addition, they are very cost-competitive with their lobe counterparts, flexible impeller FIP pumps or diaphragm versions.

We offer various types of dispensers; manual and automatic. The mass container supplied with the dispenser can be heated, equipped with a stirrer or pressurized. Our dispensers are perfect for handling products with different rheological properties. With their use, you can dose from water to the densest peelings with a high content of solids of various origins and hardness: from ground walnut shells to shredded shells.

If you need proven and efficient rotary tables, we encourage you to familiarize yourself with the offer of the TKmatik company. They are successfully operating at the leading cosmetics manufacturers in Poland. We produce rotary tables for a wide range of cosmetic products. They allow for a significant optimization of the packaging process of cosmetics and chemical industry products.

With the use of lining tables manufactured by TKmatik, our clients have the option of combining several transport lines into one packaging line. This allows for a significant optimization of work with packaging in the material flow system in various industries. We cordially invite you to familiarize yourself with our offer!

Our offer includes a wide range of transporters, from warehouse transporters to technologically advanced plate and modular transporters. We offer them in a different standard of performance in order to meet the specific expectations of the client as much as possible. These are custom components, the appearance and complexity of the structure depends on your requirements. If you are interested in the offer for TKmatik transporters, please contact us!

Our counters are used for counting and rewinding roll labels. With their use, you can accurately count both transparent and metallized labels with high speed. In addition, they are characterized by a compact design and simple and intuitive operation.

Our production of sealing heater unit are perfect for handling jars made of various materials. They have a flexible heater and the ability to smoothly adjust the pressure of the heater. In addition, they are characterized by stepless regulation of the time and temperature of the warmer. They can be ordered as autonomous components or additionally equipped with seal feeder. In addition, they can be supplied with the Uniline 2000 line.

Our feeders will allow you to very precisely feed various types of seal. Additionally, they can perform pre-heating operations. Another advantage is their interchangeable magazines, thanks to which the possible exchange of the seal is very short. Like our heaters, the feeders can be supplied with the Uniline 2000

We offer a proven construction of vibrating sorters. They allow the automatic feeding of a wide range of closures, including fliptops, caps, pumps or atomizers. They are characterized by high efficiency, relatively small dimensions and the possibility of significantly improving the process of packaging products with their use.

We encourage you to take advantage of the TKmatik offer for cappers of various designs. We have jaw and roller cappers. They are characterized by the possibility of stepless torque adjustment and precise control of turning, thanks to the use of a servo mechanism in them. Our capping machines are perfect for closing jars, pumps, caps and atomizers made of various materials (glass, plastic and metallized)

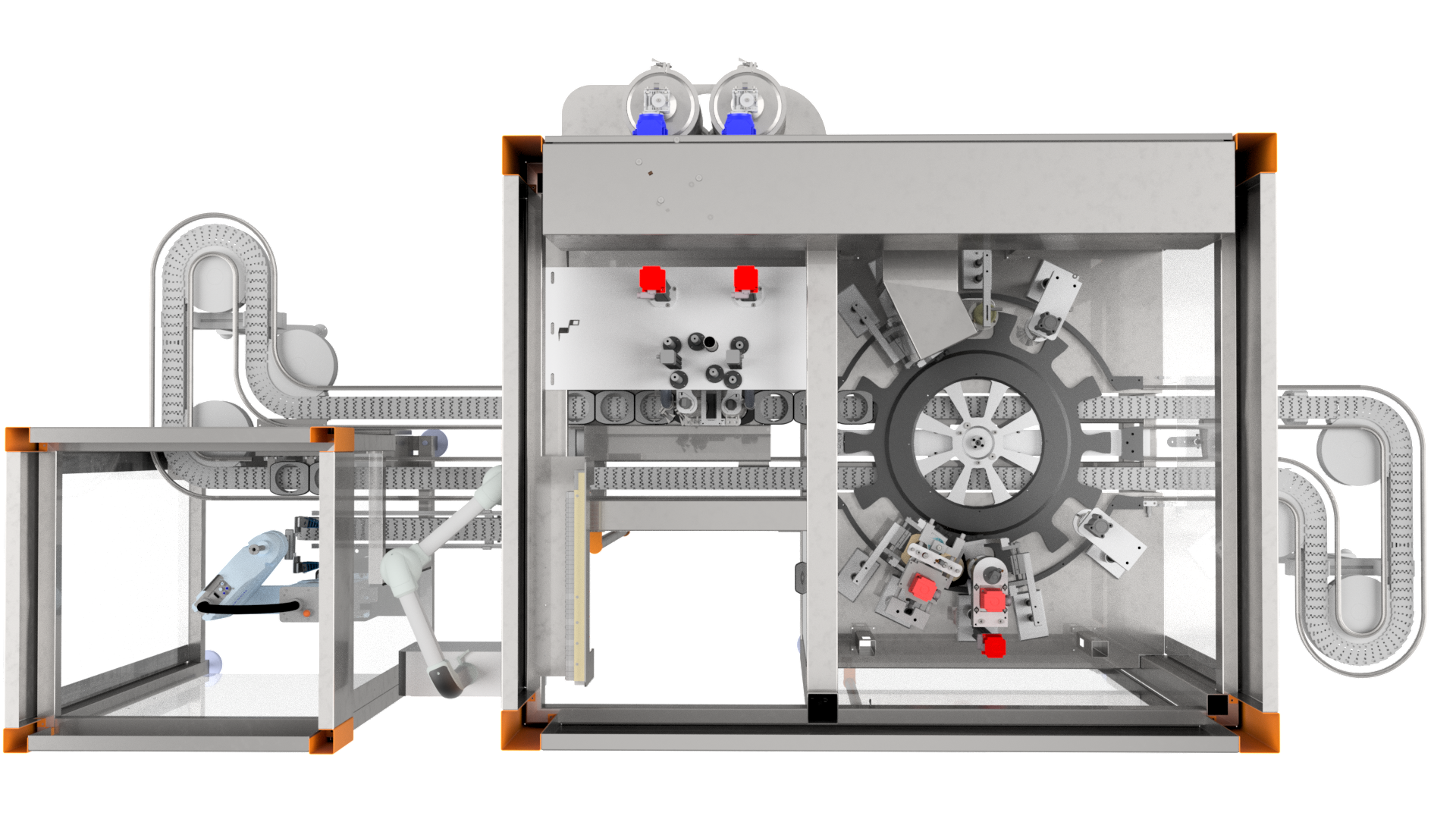

Monoblocks are a packaging device designed for a specific product with a capacity of up to 3,000 packages per hour. They are used for automatic mass dosing and closing packages. The devices offered by TKMATIK allow for various levels of automation of the packaging process.

Device characteristics: